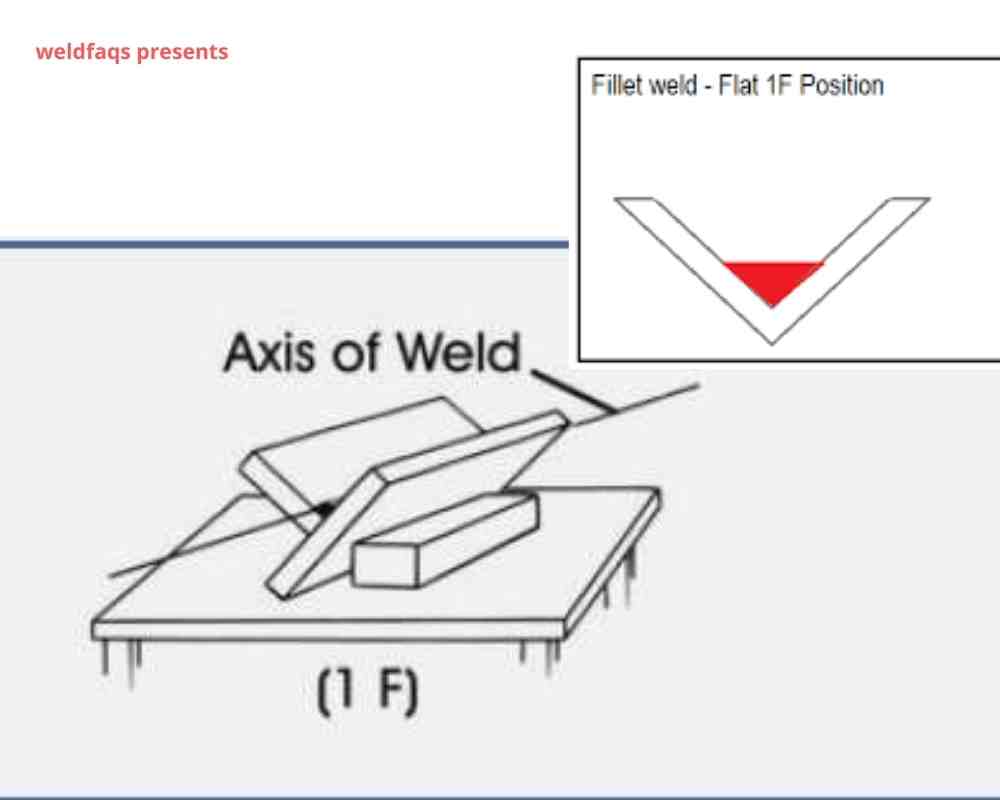

In welding, the number 1 is used to refer to the flat welding position. This is perhaps the easiest position to weld out of all the welding positions. It is typically used to weld a joint on a flat surface.

The flat welding position will be denoted as either 1F or 1G, which indicates the type of weld used. The 1F position indicates a fillet flat welding position, while 1G indicates a groove weld in the flat position.

In this article, let’s look at the 1F welding position and how to perform this weld position, as well as some of the characteristics of this weld position and when to use it.

All About the 1f welding position

What makes the flat position easier than other positions is the fact that you are not fighting gravity. As such, the weld puddle remains fluid and evenly wets into the joint. This means you can run your welder hotter and use a higher deposition rate than in other positions.

There is no welding process you cannot implement in the flat position. The only thing to note is the recommended techniques to use to achieve the best results. For instance, when stick welding, it is recommended to use a drag technique instead of a push technique.

This is because stick welding results in a slag. The flat position can be used for but, fillet and groove welding.

How to weld in the 1f welding position

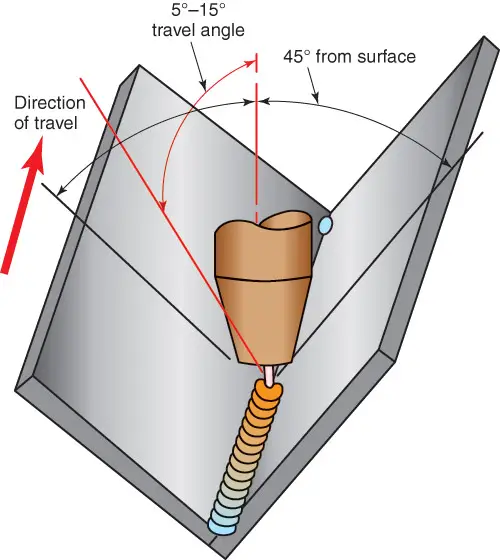

Since we will be performing a fillet weld in this position, the two most important things to note will be the work angle and the travel angle. Also, the settings of the welder. For this step, we will be using a stick welder and a 3/32 inch 7018 electrode.

Step 1: Set up the welder

To perform this weld, we will be using 100 amps to 140 amps. This will be sufficient for making three passes on the weld angle, which is what you want to do. As for the position of the electrode, it needs to be positioned at a work angle of 90 degrees.

If welding thinner sheets, use a lower amperage of between 65 and 100 amps.

Step two: start welding

As mentioned, for stick welding, you want to use a drag technique. Use a travel angle of between 10 and 15 degrees. For thicker sheets of metal, you want to do three passes to ensure a good weld penetration.

Conclusion

The 1f weld position is used to make fillet joints between two surfaces. This position is easy to weld and does not have some of the difficulties of some other weld positions. It is also called the downhand position, and the molten metal is drawn downward into the joint in this position.

Any electrode with a “1” as its third number in its designation can be used to weld in this position. This means you can use a wide variety of electrodes to weld in this position, which makes it more accessible for beginners.