A welding position means the posture you need to assume towards the workpiece you are welding. In some cases, you will need to weld the workpiece in the position you find it and not adjust it in any way.

So what are the different welding positions you can use when welding? There are a number of welding positions, and in this article, we will look at the five basic welding positions and 1G, 2G, 3G, 4G, 5G, 6G/6GR pipe welding positions.

What Is Welding Position?

In welding, the welding position is the relative position of the welding gun (hand-held welding torch) and workpiece. The welding gun is held differently for each welding process because different positions affect what type of weld joint can be made. Welding joints are classified according to how the weld pool forms in each particular position. There Are five basic welding positions.

what are the 5 welding positions?

Five basic welding positions are shown below there;

1. Flat Position

This Position is the most common and easiest to learn. The workpiece being welded is horizontal and parallel with the ground (or whatever surface it’s on) in a flat position. It also means that your eyes should be looking straight down at the workpiece, not up or sideways at all.

- Travel Angle of Flat Position Is 5-15%

- You can tilt the electrode 5 to 15 degrees angle from its 90-degree Position, which is called the travel angle of the electrode.

- You Have to operate the electrode from the left side to the right side.

2. Horizontal Position

in this Position, the welded workpiece is horizontal and parallel with the ground (or whatever surface it’s on). It also means that your eyes should be looking straight down at the workpiece, not up or sideways at all.

- Travel Angle and operating system as same as Flat Position

3. Vertical Position

The third welding position is vertical since this makes an upright line from top to bottom when viewed from above, and the workpiece being welded is perpendicular to this line.

4. Overhead Position

Overhead Position means that it’s done with your head looking upwards and down towards whatever you’re working on. You can also do this by holding something in front of your face (like a broom) so that you have an idea of what an “overhead” position looks like. The travel angle of this Position is up to 20 degrees.

5. Inclined Position

The fifth and final welding position is inclined, which means that something has been slanted at an angle other than vertical or horizontal. This process can be done by propping a workpiece up against two objects, so it lays across them at an angle of less than 90 degrees (or to make this easy: at an angle of less than 45 degrees).

The Main Types of weld

1. Fillet Weld

Fillet weld is a process of joining two metals when they are at 90 degrees angles. They create a triangle shape that may have a concave, flat, or convex surface. The two metal intersections join in a T joint or a Lap Joint.

2. Groove weld

When Two metals joints are welded between their surfaces or their edges or both their surface and edges is called groove weld. They create a V, J, or U-shaped cross-section.

The Welding Symbols For Different Positions

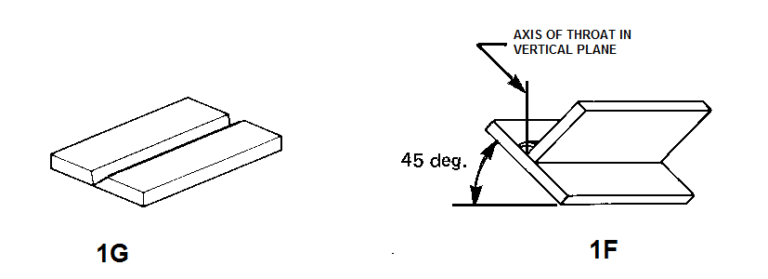

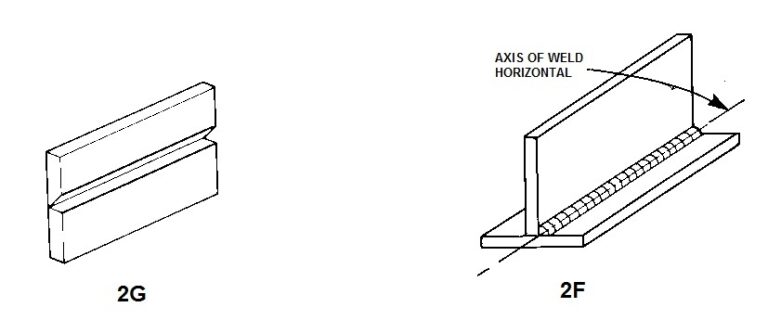

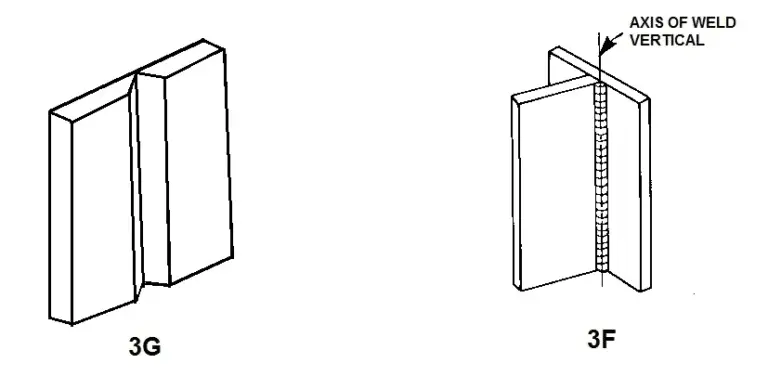

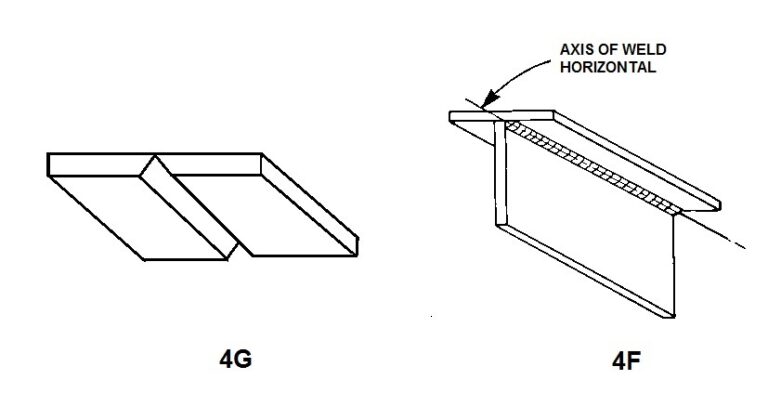

| Welding Symbol | Weld Types | Welding Position |

| 1F | Fillet Weld | Flat Position |

| 1G | Groove Weld | Flat Position |

| 2F | Fillet Weld | Horizontal Position |

| 2G | Groove Weld | Horizontal Position |

| 3F | Fillet Weld | Vertical Position |

| 3G | Groove Weld | Vertical Position |

| 4F | Fillet Weld | Overhead Position |

| 4G | Groove Weld | Overhead Position |

1G, 2G, 3G, 4G, 5G, 6G/6GR welding Positions

1G plate and Pipe Welding Position

This is the easiest weld position and can be learned quickly. The number “1” refers to the flat position, while the letter “G” refers to the groove weld. In the flat position, the joint or workpiece to be welded is placed under the welding torch.

In this regard, the molten metal flows downward into the joint. The result is easy to accomplish weld. This weld position can be used to perform groove, fillet, and butt welds.

2G plate and Pipe Welding Position

The horizontal or 2G position is a little bit more complicated than the flat position. In this position, the workpiece is placed parallel to your body when welding. Thus the workpiece remains in front of you when welding.

This position can be used to achieve either a fillet or groove weld. For a fillet weld, the torch will be held at a 45-degree angle.

3G Plate or Vertical Uphill Position

In this position, both the weld and workpiece are positioned vertically. One problem with this is the molten metal’s tendency to flow downward and pill up due to gravity. To remedy this, the torch has to be held at a 45-degree angle.

Also, you use the low metal of the workpiece to achieve a vertical uphill position.

3G Plate or Vertical Downhill Position

Like the vertical uphill position, the workpiece is also placed in a vertical position in the vertical downhill position. However, instead of using the workpiece’s lower metal, you use the upper part of the workpiece.

4G Plate or Overhead Position

This is quite a challenging position to pull off. Ideally, you will be below the workpiece to perform an overhead weld. This, of course, presents a number of challenges. The metal deposited to the joint tends to sag resulting in a higher crown bead.

To prevent this, it is advisable to keep the molten puddle small. If the puddle becomes too large, remove the torch to cool down before continuing.

This position can also be achieved by holding the torch at a 45-degree angle while being under the workpiece.

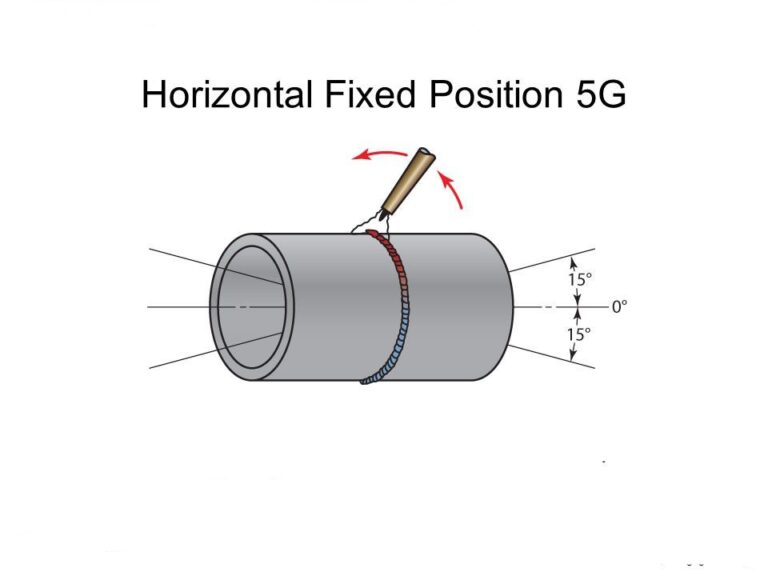

5G Pipe Welding Positions

The 5G welding positions are complex welding positions and can be classified into several. These are;

5G Vertical or Uphill Position:

This is an upward welding position used mainly for pipe welding. In this position, welders assume three welding positions in a sequence. It starts from overhead to a horizontal and then to a flat position. During the sequence, the pipe or workpiece is not turned or rotated.

5G Downhill Position:

Similar to the uphill position, the downhill position follows a sequence of three welding positions. In this case, the welder starts from a flat position, then horizontal, and ends with the overhead position.

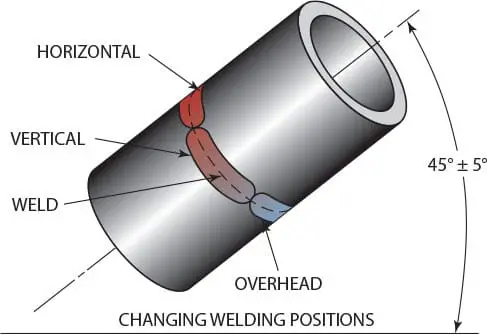

6G Pipe Welding Position

This is the most challenging welding position and is used as a pre-condition for getting certified. In this weld position, one pipe is positioned at a 45-degree angle to the other. There are three weld positions to assume.

The first is the horizontal position, which is difficult and is followed by the flat position and finally, the vertical position. A Lot of practice is needed to perfect this weld position.

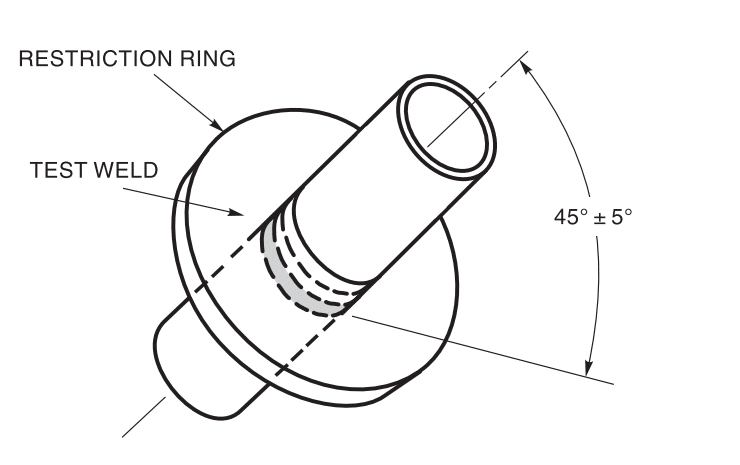

6GR Pipe Welding Position

This is another 6G weld position that is also challenging. The “R” in the name stands for restricted. In this position, welding is performed in a ring mode. What this means is that a steel plate is placed under the weld site with an inch gap.

This position is used when you need to attach a pipe to another structure or when there are impediments such as brackets, and walls.

Application Sectors Of these Positions

- 1G, 2G, 3G and 4G plate welding positions uses in the fabrication and installation of tanks, vessel, structural, shipbuilding and aeronotics

- 1G, 2G, 5G and 6G pipe welding positions are used in the fabrication and installation of piping and pipelines for industrila plants, oil and gas industry, chemical plants and other piping and pipelines industries

- 6GR is used in installation of offshore structure and other structure that have the TKY configuration

Relationship Between Welding Position And Welder Certification

To get a certification as a welder, you need to pass welder certification tests. These tests are based on several things key, among them welding positions.

As such, if you can weld in either the vertical or overhead positions, you qualify for a 3G or 4G certification. For the latter certification, you do not need to pass any qualification tests below those levels.

More experienced welders can apply for more than a 4G certification. In particular, pipe welders can apply for a 5G and 6G certification. These two are used for the most complex welding positions.

Therefore they require more experience. The 6G certification is seen as the gold standard of welding certification. Welders with this certification can weld all-around a stationary pipe.

From this, the weld certification you can qualify for will depend mainly on the welding positions you are proficient with.

Which Welding Position Should You Use?

It goes without saying, but the welding position you choose will depend on how the placement of the workpiece. However, it is worth noting that there are other factors that will influence which welding position you are able to work with.

Experience

The most experienced welders are more than comfortable welding in the most complex welding positions. However, if you are relatively new to welding, the flat position will be ideal.

A welder’s experience will also influence their certification. Therefore, some welding positions will require more experienced hands.

The Electrode

Different electrodes are suited to different welding positions. Electrodes are unique number designations. These numbers refer to the characteristics of the electrode.

And the third digit in an electrode’s number designation refers to the welding position it can be used in. For instance, the number “1” means an electrode can be used in all positions.

On the other hand, the number “2” means that the electrode can only be used in either the horizontal or flat positions.

The welding process

As with electrodes, different welding processes work differently depending on the weld position. For example, overhead MIG welding may require higher amperage and short stick out than stick welding.

Conclusion

Understanding the different welding positions will be important in your certification. Typically, you will be tested on either all welding positions or some of them, depending on the certificate.