The exhaust pipe is more prone to wear and tear than most other parts of a vehicle. And with some basic welding knowledge, you can repair the exhaust pipe of your car.

Due to its thinness, MIG welding is recommended for repairing an exhaust pipe. However, sometimes you may not have an MG welder around. Also, the exhaust pipe may be too dirty for a MIG welder.

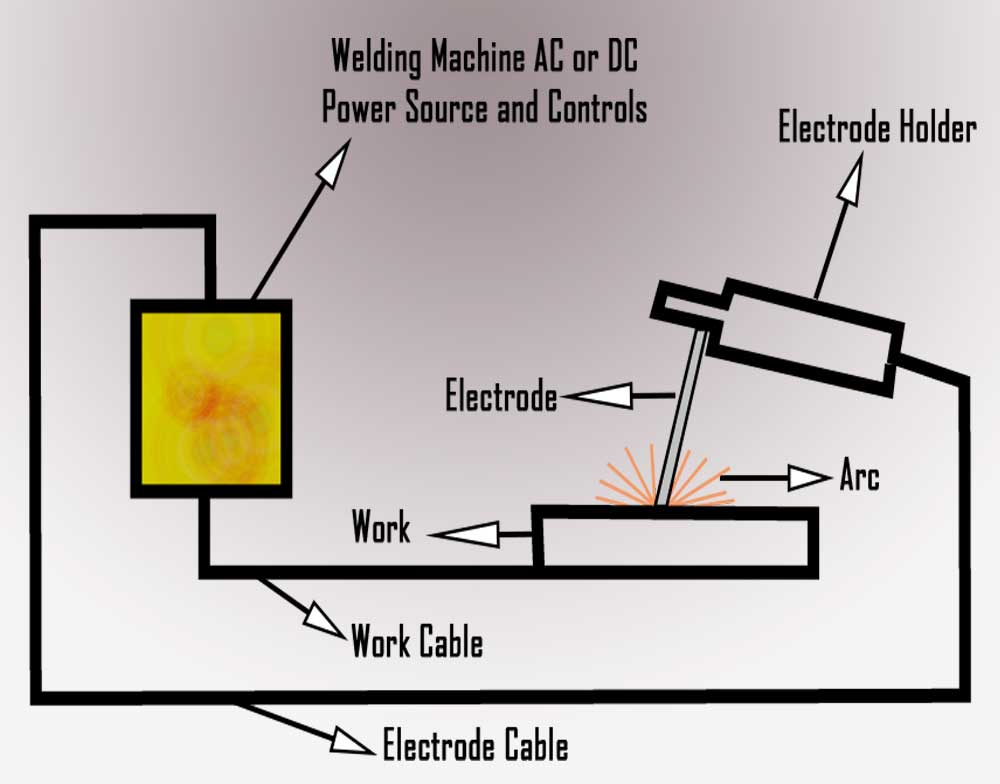

Thankfully, it is possible to stick weld an exhaust pipe. That being said, let’s look at stick welding exhaust pipes.

How to stick weld an exhaust pipe

Step one: Choose The Right Rod For Welding

As mentioned, exhaust pipes are made from pretty thin metal. Therefore, you need a welding rod that can handle light metals. One of the best rods for thin metal is the 6011. Alternatively, you can opt for the 6013.

These two rods work best on thin sheets of metal and are more forgiving on dirty or painted surfaces.

Step two: Cut The Pipe In Proper Way

When welding the pipe for the repair, you will need to cut it first. It is important to note that cutting the pipe will influence how the finished product will look like for precision first mark where you want to cut the pipe.

Next, use a hacksaw or a chain pipe cutter to cut the pipe. Ensure the cut is as straight as humanly possible.

Step three: Clamp The Pieces

Ideally, you will be welding a new piece of tubing to your exhaust pipe. This means clamping the two pieces will be necessary. You can use C-clamps to clamp the two pieces together. Any adjustments you need to make to how the pieces are aligned should be made before welding.

Step Four: Spot Weld

Given the thinness of exhaust tubing, you will have to do spot welding. This is where you make three or four tiny around the tubing’s circumference. The heat produced when welding will prevent the tubing from warping.

Step Five: Complete

After making the spot welds all around the tubing, weld the remaining gaps in the tube. Ensure you weld all around the tubing.

Stick welding safety tips

Stick welding produces a lot of heat, so it is essential to work in an environment that fires safely. Also, there shouldn’t be any clutter that can catch fire quickly in the area.

- Wear a welding mask and gloves to protect your eyes from the ultra-violet light produced when welding and to protect exposed skin from flying hot sparks

- Wear fire-resistant clothes, gloves, and shoes to protect your entire body from flying sparks generated when welding.

- Make sure you remove the exhaust tubing from the vehicle for welding and should not be welded while still attached to the car.

- Maintain a low amperage on your welding machine to avoid burning through the exhaust tubing. In this case a 120v stick welder will be best option.

Conclusion

Welding an exhaust pipe requires a lot of care. They are usually made of steel alloy consisting of stainless steel and Inconel. On top of that, exhaust pipes are generally thin, requiring extra caution when welding stainless steel to prevent burn through.