A resistance spot welder is the best for making spot welds. Unfortunately, these types of welders are pricey and not accessible to everyone. Fortunately, spot welding can also be done using a MIG welder.

If you have a MIG welder, using it for spot welding will be cheaper than purchasing a resistance spot welder. This brings us to the question of how to spot weld with a MIG welder.

how to spot weld with a MIG welder

Spot welding with a MIG welder will be different from doing it with a resistance spot welder. With the latter, the two sheet metals to be fused are put in between two electrodes. With a MIG welder, you will have to improvise and use a rosette or plug weld.

Spot welding with a MIG welder step by step

Step One: Prepare The Sheet Metals

Before welding the two sheet metals together, it is always recommended to clean them. MIG welding works best on clean and unpainted surfaces. Once cleaning is done, where necessary, the next step is to punch holes on the upper metal.

On the piece that goes on top, punch 5/16 inch holes if the sheet metal is 18 gauge. If the metals are thinner, you can reduce the size of the holes. On the other hand, if the metals are thicker, you can increase the holes’ size.

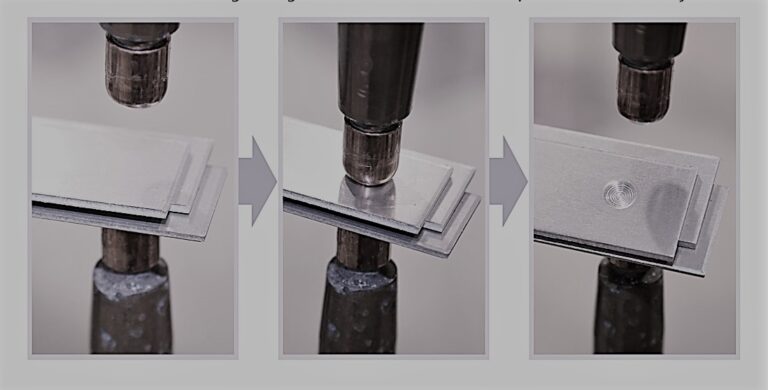

Step Two: Clamp The Metals Together

The next step is to clamp the two metals together. This is to ensure the two metals do not move about or shake when welding. The piece of metal with the holes should come on top. You can use metal clamps or pliers to clamp the two sheet metals.

Step Three: Welding

When the two metals are clamped together, you can now start welding them together. However, if there are any adjustments to be made, ensure they are made before welding.

When welding starts from the center of the hole and then moves the welding torch around the hole covering its entire circumference, there is no rule on the direction you should take. Thus you can do it in a clockwise direction or anti-clockwise direction.

Step Four: Finishing Touches

In some cases, the weld may go out of the diameter of the hole. You can use a grinder to smoothen the edges to have a nice smooth finish.

Spot welding with a MIG welder tips

- To get good results to practice on two sheets of scrap metal first. The two must be of the same thickness as the sheet metals you want to weld. Experiment with different welder settings on the scrap metal to the results.

- It is recommended to use a spot nozzle instead of a standard MIG nozzle. The spot nozzle fits most MIG welders.

- Ensure the welding wire sits slightly below the spot nozzle’s standoffs.

Conclusion

Resistance spot welder is mostly done in vehicle manufacturing plants. Using the same welding process in your garage can be expensive. However, it is possible to convert MIG welder to spot welder using spot welder nozzles.