When you want to joint two small pipes compression fittings will come in handy. So what are compression fittings? These are couplings typically made of brass or copper used to connect two tubes or pipes with small flow diameters.

These fittings are used in low-pressure applications. You can use them if the pressure is between -5ps to 125 psi. There are two types of compression fittings that we are going to look at below, Type A and Type B compression fittings.

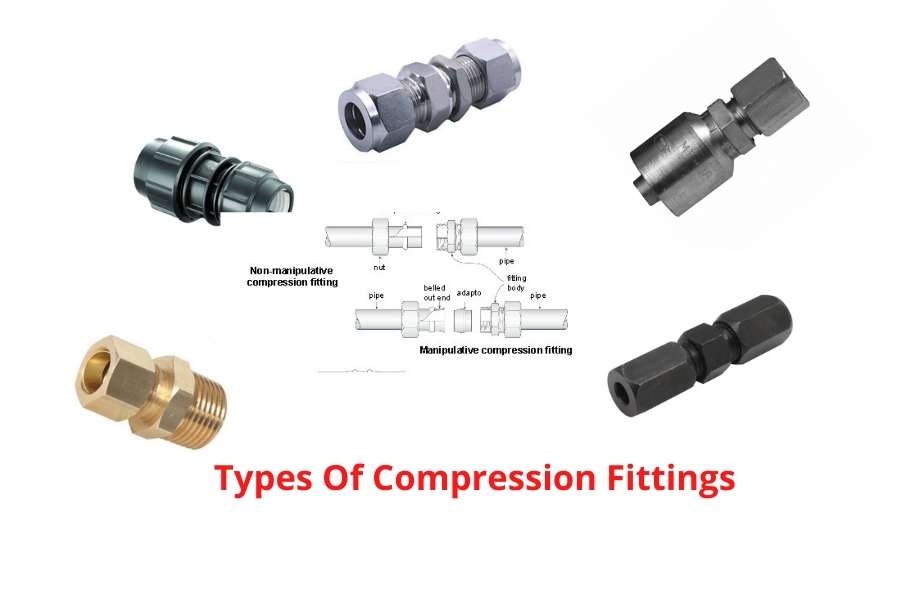

Types Of compression Fittings

There are mainly 2 types of compression fittings. Here are the details of these two types of compression fittings.

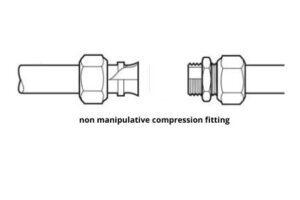

1. Type A Compression Fitting

This type of compression fitting is also called non-manipulative fitting. As its name vaguely suggests, you do not have to do any modification to the pipe or tubing to install this fitting. You can install it using an ordinary wrench and these types of fittings are typically used for water pipe connections.

How To Install A Type Compression Fitting

The installation process of a compression fitting will depend on the type of pipe. For the purposes of this section, we will be using a copper pipe and a plastic pipe.

Step One: Slide The Nut

First, take the nut and slide it over the copper pipe or plastic pipe. Make sure the nut’s threads face the compression fitting. Then take the brass ring and also slide it over the copper tube. For plastic pipes, you are going to use a plastic compression sleeve.

The fat end of the sleeve should face the nut with the tapered end facing the fitting. Also for the plastic tube, you will use the brass tube and insert it into the tube.

Step Two: Insert Tube To The Fitting

Next, take the copper tubing or plastic pipe and insert it into the back of the compression fitting. Then hand tighten the nut to the fitting until you can’t tighten it anymore. Then take a wrench and tighten it further using one half revolution.

Type A Compression Fitting Uses

- For joining thin-walled piped used in plumbing

- Used to connect two plastic or copper pipes together

- Used to connect hot and cold water faucets in showers

- Used to connect toilet stop valves.

How To Remove A Compression Fitting

Removing a Type A Compression fitting is relatively easy. Take a wrench and turn the nut that connects the pipe to the fitting. Once the nut is loose enough remove the pipe from the fitting.

When And When Not To Use Type A Compression Fitting

Compression fittings are ideal for connecting small diameter pipes and tubings with low pressure of between -5 and 125 PSI. Also, use these fittings with a permanent or stationary connection.

Compression fittings are designed to restrict pipe movement away from the fitting. Take care not to overtighten the fitting when installing one.

So when should you not use a compression fitting? These fittings should not be used with bent tubes or pipes.

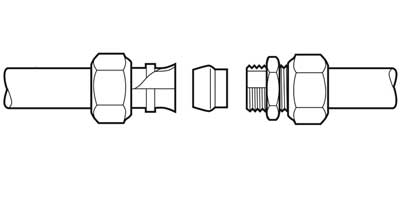

2. Type B Connection Fitting

This type of connection fitting is also called manipulative fitting. Thes types of fittings require you to modify the pipe or tube you are installing them on, hence the name. Typically, you need to flare the tubing to insert this type of compression fitting.

How To Install Type B Compression Fitting

To install this type of compression fitting, you will follow the same steps as the non-manipulative type, with one addition.

Step One: Slide The Compression Nut

As with the non-manipulative fitting you need to slide the nut over the pipe first. The threads should be facing towards the compression fitting.

Step Two: Flaring The Pipe

The first thing to do is to flare the pipe you want to install a compression fitting. There are plenty of flaring tools you can buy for this purpose. It is important to note that if you are working with a tube you want a 45-degree angle flare. If working with a pipe you will want a 37-degree angle flare.

Step Three: Insert The Fitting

Next insert the compression fitting into the flared end of the pipe and tighten the compression nut over it with your hands. Use a wrench to tighten it further similar to what you would do with a non-manipulative fitting.

Removing The Fitting

The process of removing the Type B compression fitting is a bit different. To pull it out of the pipe you need a specialized pulling tool. This tool will help you slide the nut and olive away from the pipe.

Type B Compression Fitting Uses

This type of fitting is less common than the non-manipulative one. And while it can be used in water faucets, it is mainly used for below-ground types of connections. Also, this type of fitting is used in gas lines.

When Not To Use It

Similar to the non-manipulative type this type cannot be used on bent pipes or tubings and is best used in permanent or stationary fixtures.

some Other Common Types of Compression Fittings

1. Flareless Compression Fittings

These types of compression fittings are mainly used with metal tubings. These do not require flaring the tube but rather compressing into the tubing forming a tight connection.

2. High-pressure Compression Fittings

These compression fittings are designed to handle high pressure than standard fittings. The nuts included with them can handle twice as much pressure as standard compression nuts. They are typically used in hydraulic power applications.

3. HDPE Compression Fittings

These types of compression fittings are mechanical in nature and are used to connect HDPE pipes to fixtures or valves. They are mainly used in plumbing and piping systems.

4. PP Compression Fittings

PP compression fittings are made from Polypropylene and offer flexibility suited for connecting PE pipes. They are used in many industries including gas, liquid gas heading, and oil installations to rainwater harvesting systems.

5. Brass Compression Fittings

As their name suggests, these are fittings made from brass. Brass is known for its anti-corrosion properties and thus these types of compression fitting are used mainly in plumbing systems.

6. Double Ferrule Compression Fittings

These types of fittings feature two deformable ferrules. These ferrules are usually made from non-ferrous metals or soft alloy metals. The fitting nut of these fittings causes the ferrules to be deformed causing a tight seal.

7. Single ferrule compression fittings

The opposite of double ferrule compression fittings, single ferrule fittings have only one ferrule that grips the tubing or pipe to create a tight seal.

8. Steel compression fittings

Similar to brass, steel compression fittings are simply fittings made from steel. These are typically made from stainless steel to prevent corrosion.

9. Hydraulic compression fittings

Hydraulic compression fittings are used to connect pipes of different diameters. The most common type is the union fitting, which has threads on both sides.