One of the most popular stick welding rods is the 6010 welding rod. It is a fast-freezing, deep penetration rod widely used in root pass welds. So what makes this rod a popular choice for stick welding applications?

The 6010 Rod Meaning

To understand why this rod is so popular, we need first to understand what kind of rod it is. We can do this by examining the numbers that make up its name. The 60 in the name refers to 60,000 pounds tensile strength.

This means the ability of the weld joint to resist being pulled apart per square inch. As for the 1 that follows the number ‘60’, it refers to the fact that this is an all-positions rod. Thus it can be used in any position flat, horizontal, vertical, or overhead.

The last 0 in the name refers to the kind of flux that this stick rod has. In particular, this rod has a high cellulose sodium coating.

Recommended 6010 welding rod at the best price

Table could not be displayed.Mechanical properties of E6010

| Tensile Strength | 60 Ksi |

| Yield Strength | 48 Ksi |

| Elongation | 22 % |

| Welding Current | DC (+) |

| Coating Type | high cellulose-coated electrode |

| Welding Position | All positions |

| CVN @ -50°F | 20 ft•lbf (27 Joules) |

| Welding Process | Stick Welding |

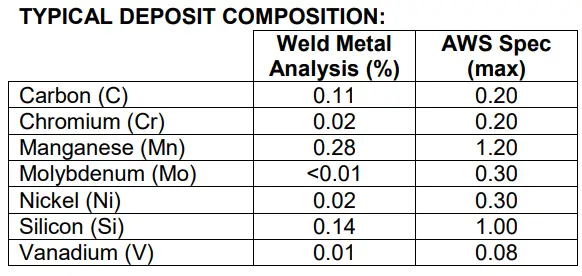

6010 Rod Chemical Composition

The 6010 rods are composed of carbon, chromium, manganese, molybdenum, nickel, phosphorus, silicon, sulfur, and vanadium.

| Weld metal | Carbon (C) | Chromium (Cr) | Manganese (Mn) | Molybdenum (Mo) | Nickel (Ni) | Silicon (Si) | Vanadium (V) |

| Weld Metal Analysis (%) | 0.11 | 0.02 | 0.28 | <0.01 | 0.02 | 0.14 | 0.01 |

| AWS Spec Max % | 0.20 | 0.20 | 1.20 | 0.30 | 0.30 | 1.00 | 0.08 |

welding parameters of 6010 Electrode

| Diameter (inch) | Diameter (mm) | Polarity | Current (amp) | Deposition Rate (lb/hr) | Deposition Efficiency (%) | Optimal Amps | Volts |

| 3/32 | 2.4 mm | DCEP | 40-70 | 1.3 | 53 | 50 | 26-29 |

| 1/8 | 3.2 mm | DCEP | 65-130 | 1.6 | 54 | 100 | 26-27 |

| 5/32 | 4.0 mm | DCEP | 90-175 | 1.9 | 55 | 140 | 26-28 |

| 3/16 | 4.8 mm | DCEP | 140-225 | 2.6 | 54 | 170 | 26-28 |

The 6010 Rod Characteristics

- The 6010 is a DC-only rod and cannot be run in AC

- This rod has fast-freezing properties and deep penetration

- It can be used in all positions, flat, horizontal, vertical, and overhead

- Being a stick welding rod, this rod can be used on rusty, dirty, or galvanized steel surfaces

- This rod produces a flat and smooth bead with a light slag that looks like paper.

- It produces minimal spatter

The 6010 Rod Uses

- Due to its fast-freezing properties, it is used in stove pipe welding

- It is also used for root pass weld due to its deep penetration

- The 6010 rods are used for out of positions welding and are also a good choice for overhead welding

- It is used in repair works that involve welding rusted or dirty metals due to its deep penetration.

Advantages and Disadvantages of the 6010 Rod

Advantages Of 6010 Electrode

- The rod has deep penetration and a high deposition rate while having minimal spatter

- It is a fast-freezing rod, which makes it more suited to overhead welding than other stick welding rods.

- The rod produces a weld puddle that distributes and wets well, which makes it ideal for vertical down and vertical up positions.

- This rod can be used in all positions and can also be used in out-of-position welding

- Its deep penetration means it works well on dirty, rusted, or galvanized surfaces.

The disadvantages

- The rod is known for its violent arc, which is difficult to control

- The whip-and-pause motion is recommended when working with this rod which can be strenuous on a welder.

6010 Rod polarity and amperage

As mentioned, this rod can only run on DC and not with AC. In terms of amperage, the rod does require a high amperage. A ⅛ inch diameter 6010 rods will run best when set to 70 to 130 amps. Thicker rods, such as 3/16 inch diameter, can require up to 225 amps.

Charpy V-Notch Impact (toughness) Requirements for E6010 type electrode

The 6010 welding rod requires a V-notch toughness rating of 20 ft-lb at 20 degrees Fahrenheit. This is based on the AWS A5.1 specifications.

How to Weld with 6010 rod

To learn how to use the 6010, we will use a ⅛ inch with the welder set to 75 amps. When using the 6010 rod one of the most important to do is avoid long arcing. Long arcing is where you have the rod not close enough to the weld metal.

You will notice long arcing when you notice sparks flying from the weld puddle. Keep the rod tight to the joint because this is a fast-freezing rod. You need to use a whip-pause motion.

Move the rod up and down or sideways while pausing. Using this whip and pause motion allows the puddle to solidify by drawing heat away from it. When using this rod, ensure you are not just whipping it.

The simple whipping will result in ripping away the weld metal. This is not what you want, but rather use a whip and pause motion.

Preferable Welding Techniques

| Welding position | Welding Technique |

| Arc Length | Average length (1/8” to 1/4”) |

| Flat | Stay ahead of the puddle and use a slight whipping motion |

| Vertical Up | Slight whipping or weaving technique |

| Vertical Down | Use higher amperage and faster travel, staying ahead of puddles |

| Overhead | Use a similar technique as for vertical up, multi-pass for build-up |

| Pipe | Use downhill travel |

The 6010 vs. 6011 welding rod

Both the 6010 and 6011 electrodes offer deep penetration and a 60,000 psi tensile strength. However, they differ in some aspects. For starters, the 6011 can be used with AC.

However, the 6010 runs more smoothly, and its slag chips off more easily than the 6011. This is why the 6010 is more commonly used for root pass welding of pipes.

So which one is better? Both have their advantages and disadvantages and come down to what you want. If you have an AC-only machine, the 6011 will make more sense. But for root pass welding, the 6010 is a better option.

Advantages of the 6010/6011 over the 7018

- The 6010 and 6011 rods offer a deep penetration than the 7018, which has shallow to medium penetration.

- In terms of the slag, the light and flaky slag of the 6010/6011 is easier to remove compared to the thick slag of the 7018

- The 6010 and 6011 rods do not require special storage or redrying, unlike the 7018, which requires drying before use

- The 6010/6011 are fast freeze electrodes better suited to overhead welding than the 7018 rods.

Frequently Asked Questions

Why is the 6010 considered hard to use?

There are welders who consider the 6010 hard to use and tend to stay away from it. So why do some people consider it hard to use? The main reason is that the rod’s arc is hard to control.

The reason for this is that the rod requires a high voltage. So if you do not provide a high enough voltage, the arch becomes unstable. Also, when you use the whip and pause motion, the arc length fluctuates, meaning the power supply needs to maintain the arc.

As such, the 6010 does require a special welding machine with the necessary software to accommodate the high voltage of the rod. Welders who do not have the necessary machines tend to stay away from the rod.

Can I use the 6010 for overhead welding?

Yes, the 6010 is an all-positions rod known for its fast-freezing properties. It is thus suited for overhead welding.

How to Store the 6010 welding rod?

Since the 6010 has a cellulose coating, reconditioning and drying are not recommended. The rod requires 3 to 7% moisture to work properly. As such, it needs to be stored at room temperature.

Also, it is recommended to store it away from a heat source. Reconditioning is not recommended as it will dry the necessary moisture of the rod. Moisture is required to produce hydrogen used by the electrode.

Conclusion

The 6010 is not the easiest rod to use; however, with its deep penetration and fast-freezing properties, it is a common rod in many industries. It is particularly suited to out of positions welding.

Last update on 2026-03-01 / Affiliate links / Images from Amazon Product Advertising API